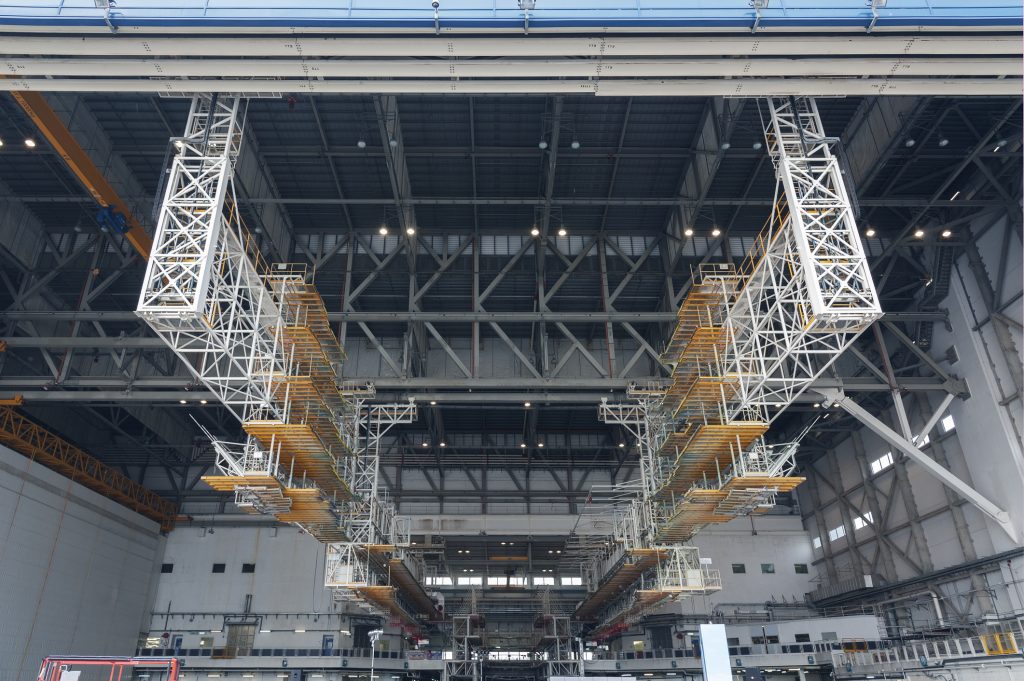

A leading Japanese airline company consulted with us about the reduction of the weight of equipment for aircraft maintenance (a dock), and our company endeavored to meet that demand, although it was a new field for us. We formed a tie-up with the airline company, overcame many hurdles by taking full advantage of the network of the UACJ Group, and completed all processes, including the selection of materials, production, and on-site installation.

Project Overview

We discussed the replacement of the current equipment made of iron with that made of aluminum for reducing weight. We aimed to offer a one-stop service, including planning, design, production, and installation of lightweight equipment.

- Planning

In cooperation with each company of the UACJ Group, we produced plans for processes from design to delivery, gave a presentation to the client, and obtained their approval. - Design, strength calculation, and price estimation

We produced design blueprints, discussed materials and specs with adequate strength exceeding that of the currently used iron, chose cooperative companies, estimated costs, and submitted estimates. - Production

We produced a structure from the welding material of UACJ, produced required parts while involving all group companies in Japan, coordinated processes, and procured parts other than aluminum materials (machined products made of iron and stainless steel, molded rubber, resin products, etc.). - Installation to handover

While overseeing the installation in an airport (a hangar), we carried out final coordination and handed over the equipment by the deadline.

Challenges

Customer challenges

- Scaffolds for maintenance need to be moved according to tasks. The currently used scaffolds are mostly made of iron, so they are heavy and require significant electric power (a large engine) to be moved. → When lightweight scaffolds made of aluminum are adopted, they can be moved manually without using electric power and can be finetuned.

Our challenges

- This project for equipment in the airline field was the first one for us. We required broad knowledge about regulations, safety standards, aircraft shapes, strength design, material selection, etc.

- Meticulous care was required for not damaging each aircraft, and a variety of materials, including cushioning materials, needed to be used or procured.

Results

- We completed the product that satisfied the client’s requirements, so the client recognized the usability of aluminum, including its light weight and resistance to corrosion, and the comprehensive capacity of the UACJ Group.

- As we needed to cooperate with a broad range of partner companies for procuring iron parts, stainless steel parts, resin, rubber, electric devices, safety signs, etc. in order to complete this product, we were able to expand our network in addition to accumulating our experience.

Because of Our Company

Coordination: To marshal group companies and members for attaining our goal!

We sometimes engage in individual projects in cooperation with some group companies, but it is rare to involve all group companies and deal with multiple tasks at the same time. Accordingly, it was very hard to spearhead the project, while summarizing issues, adjusting schedules, etc. among the client and related companies, in order to attain our goal. We were able to lead that project, because we visit production sites on a daily basis and understand the manufacturing processes and situations of clients and suppliers.

Procurement: We involved all group companies, but we still needed more suppliers.

Aluminum played a major role in reducing weight, but it was impossible to produce a structure with a height of over 15 m (equivalent to a 5-story building) from aluminum only. It was necessary to procure a broad range of materials, including iron, stainless steel, resin, and rubber, but we were able to do so by utilizing our broad procurement network without sticking to non-ferrous materials. This indicates our significant strength.