Our Business Domains

Development Support + Additional Value

Combining the specialized development support in which our strength as a manufacturer-affiliated company is utilized with the global manufacturing and distribution networks that our company has formed by ourselves beyond the scope of non-ferrous metals, our company helps deal with a broad range of issues relating to development in a one-stop manner.

Challenges in manufacturing

Selection and procurement of optimal materials

Selection of processing methods and processing factories

Trial production, evaluation, and quality improvement

Building a stable logistics and procurement network

Our strengths

We offer one-stop and optimal development support that fully utilizes the value of materials.

Specialized development support by a material manufacturer

Comprehensive development support that can be offered only by a manufacturer-affiliated company

Material development

Analysis

Assessment

Examination

Our proprietary manufacturing network

A diverse range of proposals that transcend conventional boundaries

Joining

Surface treatment

Molding

Machining

Logistics services in which our company has extensive experience

Borderless and timely global logistics

Export, import, and logistics agency services

Inventory control

Examples of support provided

Material development

- Development and selection of alloys

- Material design and trial production

Analysis

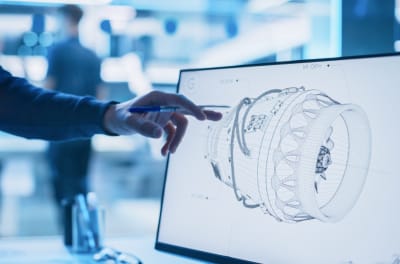

- Composition analysis

- Shape analysis (cross section, 3D scanning, etc.)

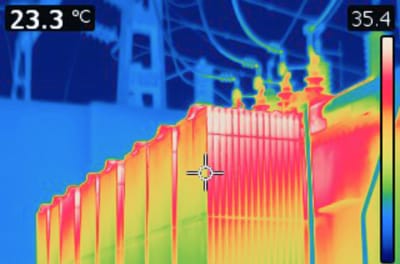

Assessment

- Assessment of corrosion resistance, reliability, etc.

- Performance evaluation

Examination

- Proposal for materials and processing based on data and assessment results

Joining

- FSW/Joining dissimilar metals/Eutectic joining/Laser welding

- Vacuum brazing

Surface treatment

- Embossing/Pear skin finishing/Etching/Blasting and others

- Plating/Coating/Anodizing/Anti-corrosion treatment/A variety of coating

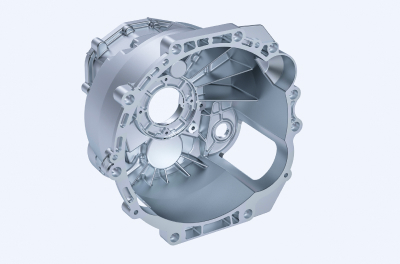

Processing/Molding

- Cutting/Machining/Ultra-precision processing

- Press

molding/Bending/Extrusion/Forging/Slitting/Rolling

- Casting (Sand mold/Die casting/Lost-wax casting, and others)

Export, import, and logistics agency services

- Handling export and import (among three countries)

- SCM

Inventory control

- Inventory management at the most suitable places in Japan and overseas

- JIT delivery

- Inspection & quality check

Example projects carried out by UACJ Trading

Introducing some cases related to development support

| Development Project | Improvement in corrosion resistance of heat exchangers of industrial kitchen equipment |

|---|---|

| Challenges | Leakage occurred due to the corrosive substances from food products, etc. and led to complaints in the market. The client hoped to develop a heat exchanger that can guarantee a certain lifespan in a corrosive environment by changing its materials. |

| Development support we provided | 1) To receive the current product and investigate corrosive components 2) To analyze the above-mentioned components, choose materials that can tolerate the corrosive environment, and submit proposal 3) To tentatively produce the core of a heat exchanger in our partner company based on the proposal 4) To conduct acceleration and performance tests using the prototype core at the site of our affiliate 5) To produce reports based on test results, have discussions with the client, and determine the final specs |

| Results | The client decided to use the materials proposed by our company from new models. While keeping manufacturing costs from augmenting, we were able to reduce complaints in the market. Namely, costs can be expected to be reduced virtually through this development project. |

| Development Project | Reduction of the weight of a compact multi-purpose conveying machine |

|---|---|

| Challenges | The current model is composed of mainly iron, so it is very heavy when a machine is conveyed to each work site. The client hopes to reduce its weight while securing necessary strength. |

| Development support we provided | 1) Provisional design with CAD and analysis with CAE based on the current model ⇒ Extraction of replaceable part 2) To consider the running in agricultural land and salt-affected land, and discuss resistant materials and surface treatment 3) To propose each part and structure, as well as processing methods to reduce costs 4) To conduct final evaluation of strength, corrosion resistance, etc. in cooperation with the client 5) To determine the final specs after trial production in our partner company |

| Results | As the first step, the client adopted aluminum materials for some parts, and aimed to reduce weight stepwise. In this development project, the client understood that weight reduction and strength enhancement can be expected by revising processing methods and structures while replacing iron with aluminum. |